NEWS

Sweating Pipelines Refurbished

Our client Enbridge Offshore required two of their corroded pipelines (16″ & 14″) and riser to be refurbished with a new protective coating system after the original coatings had failed. This system required minimum surface preparation and the ability to be applied on both wet and dry substrate.

The challenge faced with this project was working in the Gulf of Mexico, where there would be humid weather conditions combined with constantly “sweating” substrate.

Ultra High Pressure water jetting was selected as the surface preparation method. This allowed Chemco to utilise its Epo-chem™ wet & rust tolerant epoxy system. One coat of solvent-free Epo-chem™ RS 500P was applied @ 150µ DFT, followed by one coat of solvent-free Epo-chem™ RA 500M @ 250µ DFT. These coating systems were applied by spray, brush and roller.

Utilising this system ensured that the work was carried out safely, on time and there was no delays due to the weather or the sweating substrate. By using UHP water jetting, it eliminated the requirement for grit blasting. This added extra savings for our client and also allowed other work (hot work) to be carried out nearby. The application of the Chemco system could be carried out on the sweating pipes without shutdown which significantly reduced downtime.

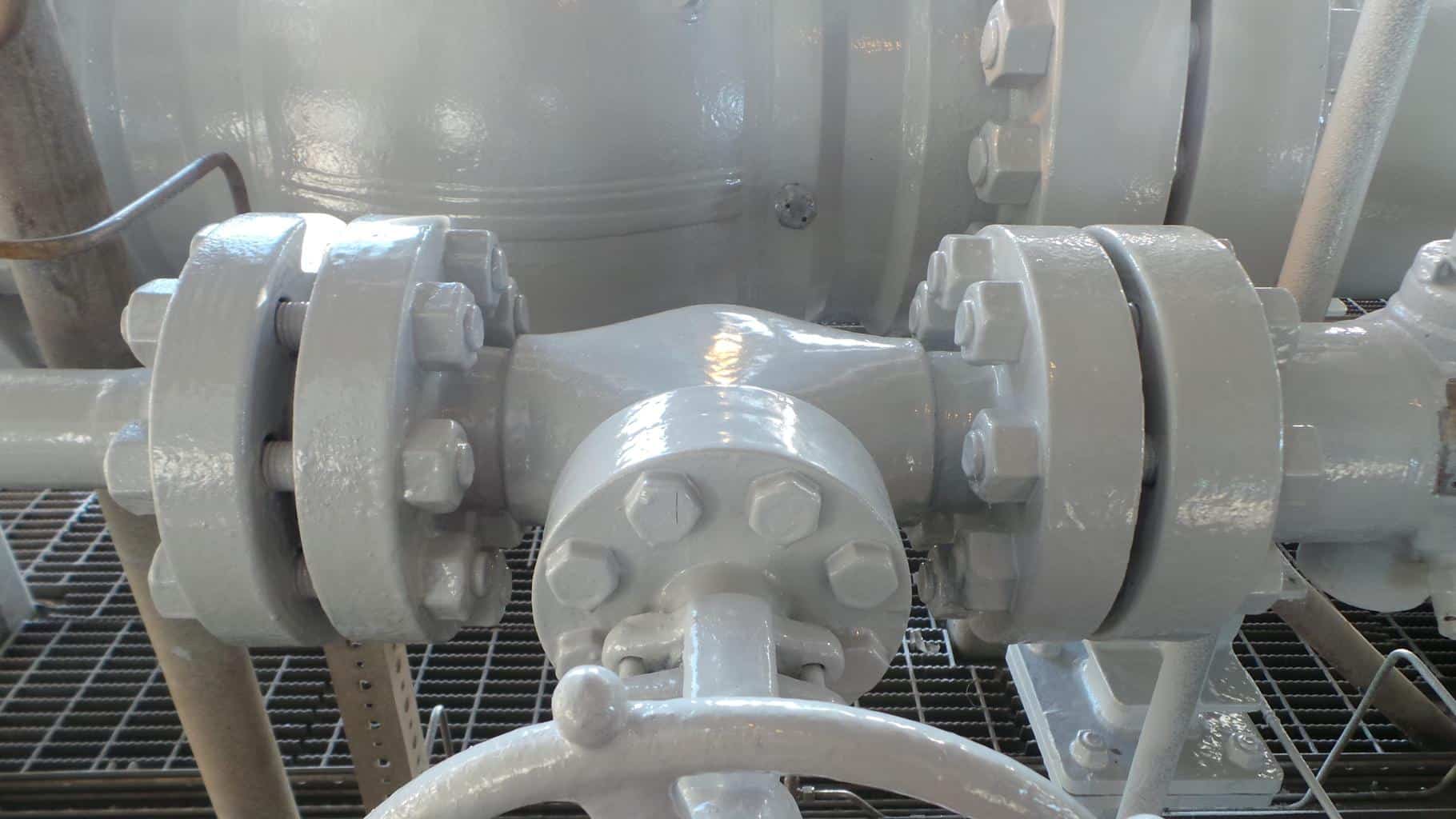

Completed Application

Completed Application

Related Products…

Contact Our Specialist Coating Advisors…

Our coating specialists can suggest the right solution for your specific application.